HCCCI Wraps up Successful Automotive Training in China

The Holy Child Central Colleges, Inc. (HCCCI) was honored to participate in a groundbreaking collaboration with the Chongqing College of Electronic Engineering, engaging in the "China-Philippines Advanced Training Course on New Automotive Intelligent Technologies." Meticulously organized by the Electronic Engineering of International Exchange and Cooperation on Development Division of Chongqing College of Electronic Engineering (CQCET), and graciously assisted by Beijing Phihua International Education Technology Co. Ltd, this event, held from November 15 to December 13, 2023, aimed at fostering global growth in the automotive sector by establishing meaningful connections between China, the Philippines, and other nations.

Representing HCCCI, Engr. Ivahn M. Bantayan, the Maintenance Manager for the Logistics and Engineering Department, participated in this unparalleled training opportunity. The program commenced on November 15, 2023 until December 15, 2023, with participants warmly welcomed upon arrival and transported from the airport to hotel, where they were greeted by the awe-inspiring landscapes of Chongqing, China

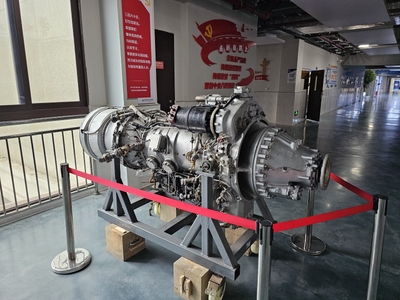

The substantive academic segment of the event unfolded on December 4, 2023, initiating classes related to automotive technology. Simultaneously, an afternoon session on Chinese culture provided a cross-cultural understanding, highlighting both the commonalities and distinctions between Chinese and Filipino traditions.

Continuing the educational journey, December 5 witnessed participants engaging in a Mandarin class centered around automotive logistics. In-depth discussions revolved around the automation landscape in China's automotive industry, focusing on both new and existing technologies.

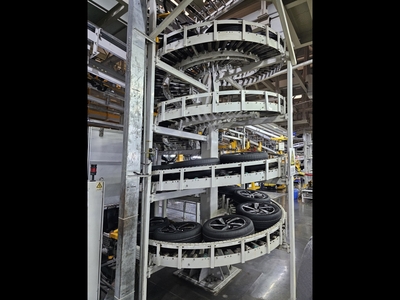

The zenith of the training occurred on December 6, with a comprehensive field trip to the facilities of Chongqing College of Electronic Engineering and a visit to SERES, a prominent car manufacturing facility. Participants witnessed for the first time the intricate processes, such as metal stamping, wielding, painting, and final assembly, all facilitated by advanced technologies, including Automotive Guided Vehicles (AVG) for production.

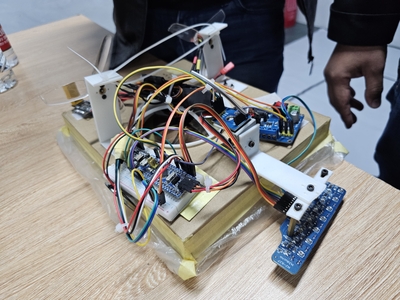

Transitioning to the practical aspect, December 7 marked the initiation of hands-on training for certification. Tasks, such as torque bolts measurement and manipulative exercises, were undertaken. In the afternoon, participants engaged in recreational activities, including a memorable hiking trip with the College of Engineering staff and a delightful visit to the Dean’s farmhouse for games. The day culminated in a Year-End Feast, fostering camaraderie and well-wishes for success and happiness.

Day 2 of training on December 8 concluded with examinations, both written and practical, signifying the formal end of classes. Subsequent days were dedicated to further enrichment through recreational activities, company tours, and hands-on experiences, offering a holistic educational experience in both the automotive and logistics industries.

On December 12, 2023, the participants of the China-Philippines Advanced Training Course on New Automotive Intelligent Technologies, had their last day, which also served as their plant tour, manufacturing company visit, and graduation day. This final day provided a comprehensive and immersive experience into the intricacies of car manufacturing, showcasing various stages of the production process.

The participants were treated to a full-scale plant tour, gaining firsthand insights into the manufacturing of automobiles. The plant tour encompassed a range of activities, allowing the participants to witness and understand key processes involved in the creation of vehicles.

One highlight of the plant tour was observing the raw material stamping phase. Participants witnessed the use of industry standard molds in shaping and stamping raw materials, providing them with a firsthand understanding of the foundational steps in car manufacturing. The sorting of stamped materials was also demonstrated, emphasizing the precision and attention to detail required in the early stages of production.

The welding process was a crucial aspect covered during the plant tour. Robotic welding arms were showcased, illustrating how stamped parts were seamlessly joined together. Another robotic arm assisted in holding the stamped parts in position, ensuring accuracy and consistency in the welding process. Additionally, participants had the opportunity to observe the scanning of welded parts, highlighting the importance of quality control and the use of technology to identify any discrepancies or mistakes in the welding process.

The final assembly line was a key focus of the plant tour, emphasizing the integration of advanced technologies in the production of vehicles. The assembly process included the assembly of vehicle body, internal components, external components, vehicle hood components, and final checking. The final checking phase involved a comprehensive check of the assembled vehicle, ensuring that all components were properly installed and met the quality standards. Advanced technologies, including Automotive Guided Vehicles (AGV) and AI assistance, were integrated into the final checking process to enhance efficiency and precision.

The final assembly line was a key focus of the plant tour, emphasizing the integration of advanced technologies in the production of vehicles. The assembly process included the assembly of vehicle body, internal components, external components, vehicle hood components, and final checking. The final checking phase involved a comprehensive check of the assembled vehicle, ensuring that all components were properly installed and met the quality standards. Advanced technologies, including Automotive Guided Vehicles (AGV) and AI assistance, were integrated into the final checking process to enhance efficiency and precision.

As the event drew to a close, Holy Child Central Colleges, Inc. extended its heartfelt appreciation to Beijing PHIHUA International Education Technology Co. Ltd, Chongqing College of Electronic Engineering, Chongqing Municipal Education Commission, and all individuals instrumental in making this cross-cultural and educational venture a resounding success. This participation not only enriched HCCCI's faculty but also made a significant contribution to the growth and development of the automotive industry in both China and the Philippines. The collaborative initiative solidifies the school's commitment to keeping pace with global industry trends and ensuring that this opportunity can be leveraged to help HCCCI’s students acquire the necessary skills for a successful career in the dynamic field of automotive technology.